SCADA Systems

Supervisory control and data acquisition (SCADA) is a system of software and hardware elements that allow industrial organizations to:

- Control industrial processes locally or at remote locations

- Monitor, gather, and process real-time data

- Directly interact with devices such as sensors, valves, pumps, motors, and more through human-machine interface (HMI) software

- Record events into a log file

SCADA systems are crucial for industrial organizations since they help to maintain efficiency, process data for smarter decisions, and communicate system issues to help mitigate downtime.

The basic SCADA architecture begins with programmable logic controllers (PLCs). PLCs are microcomputers that communicate with an array of objects such as factory machines, HMIs, sensors, and end devices, and then route the information from those devices to computers with SCADA software. The SCADA software processes, distributes, and displays the data, helping operators and technicians analyze the data and make important decisions.

The engineers at Upstate Electrical Technologies are proficient in the use of the following SCADA software packages:

- Wonderware

- GE Digital iFix

- GE Digital Cimplicity

- Rockwell Factory Talk View ME/SE, PanelView

- AutomationDirect C-More

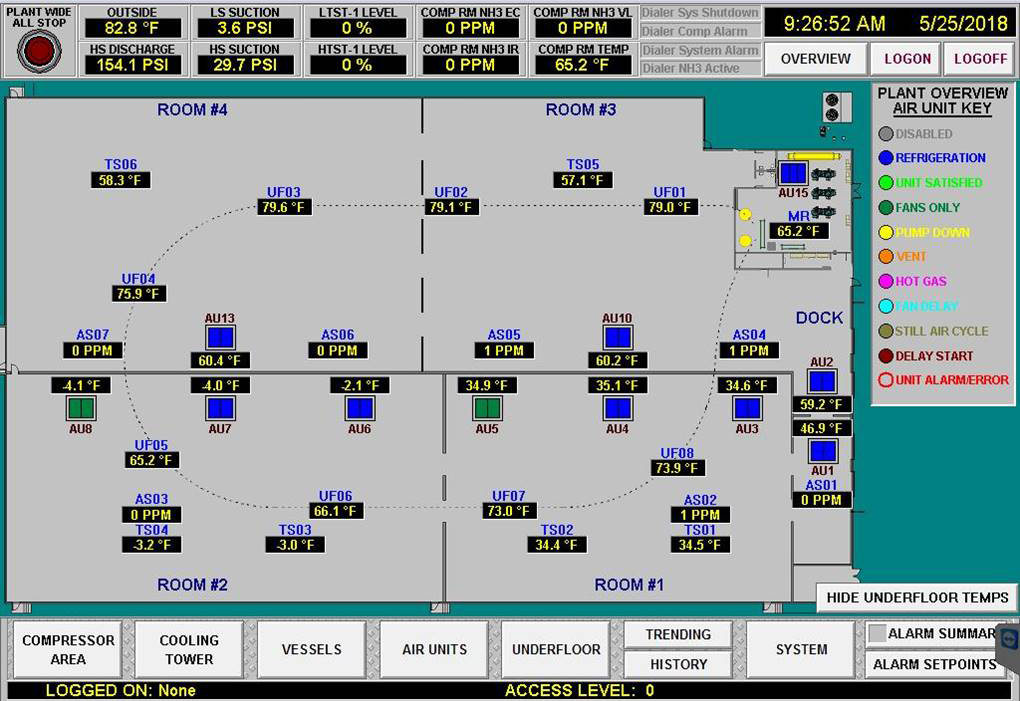

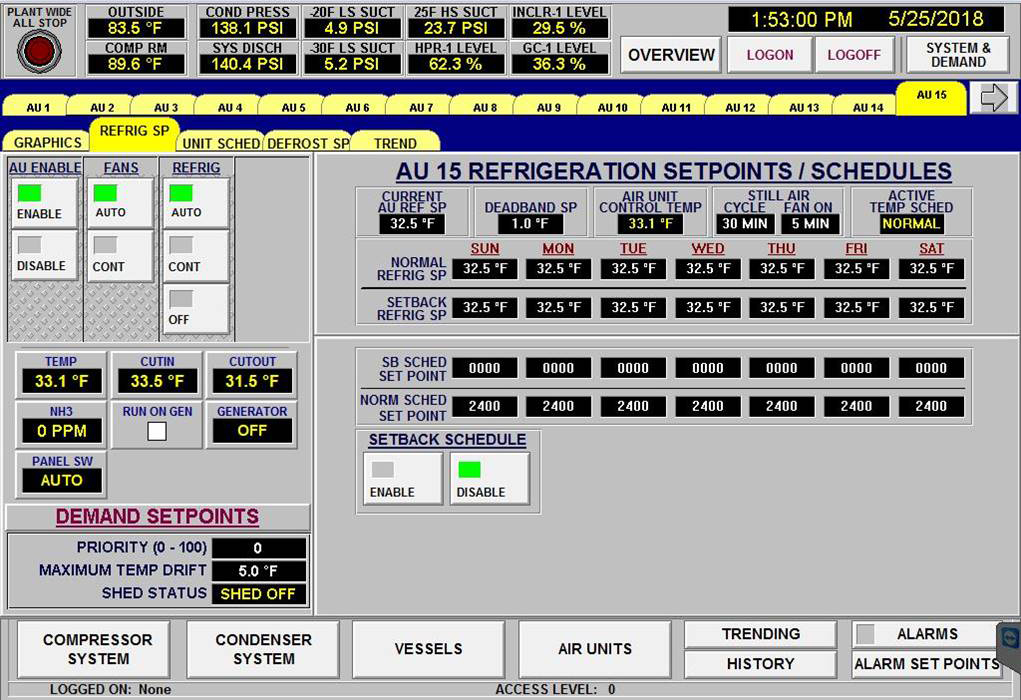

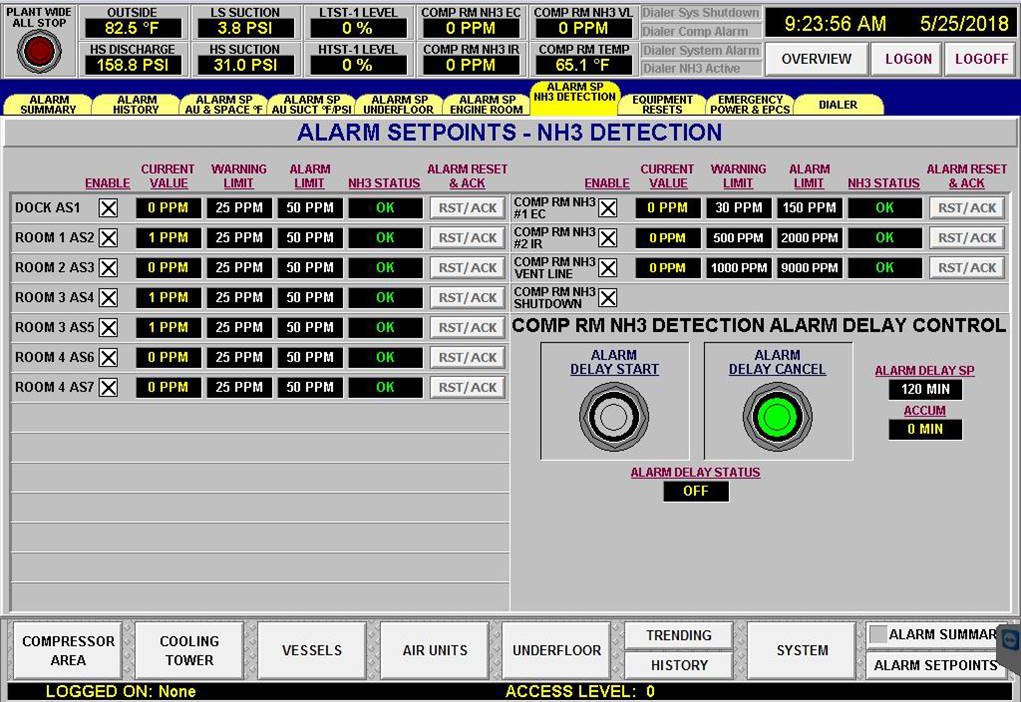

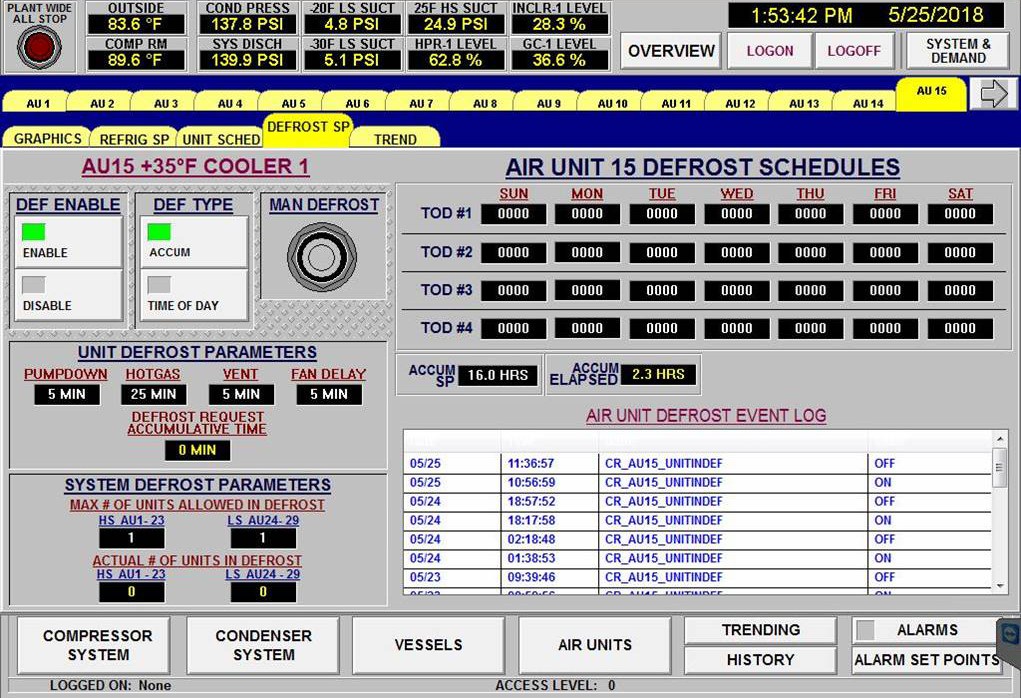

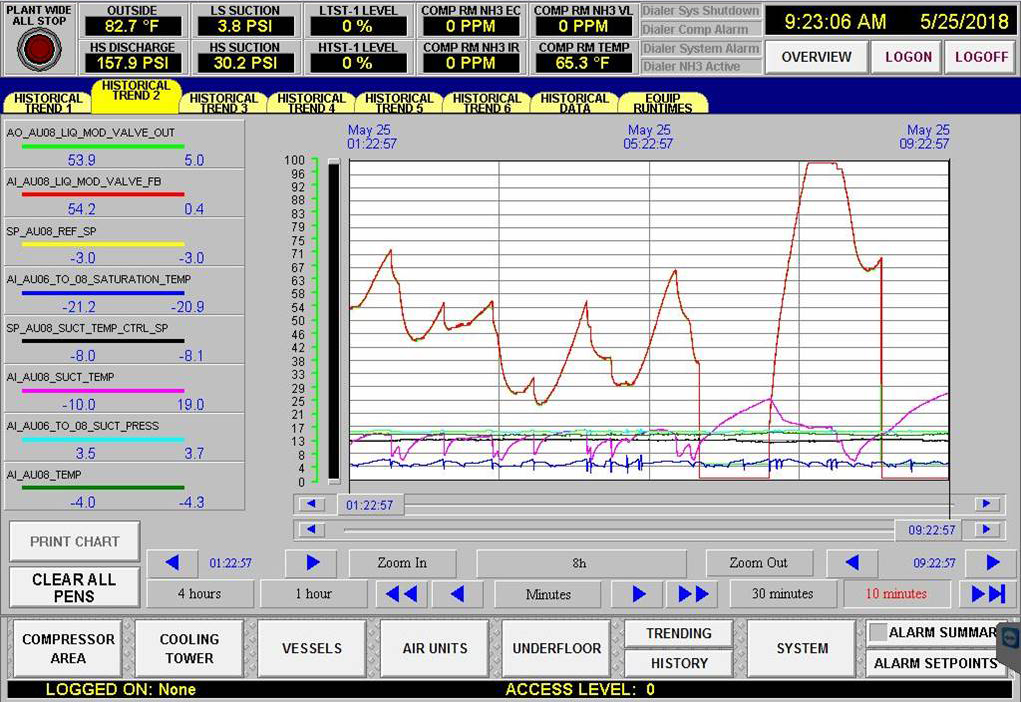

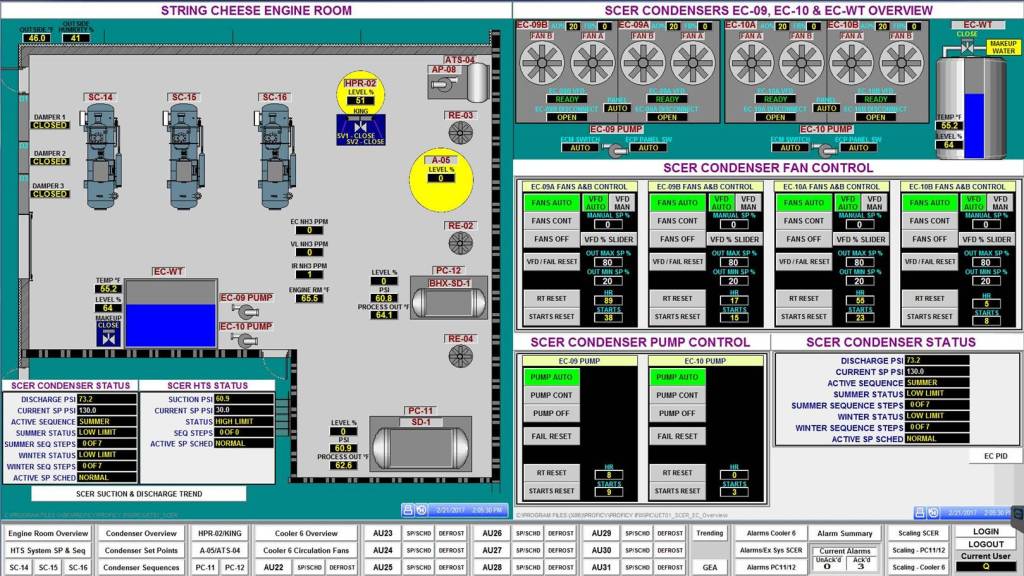

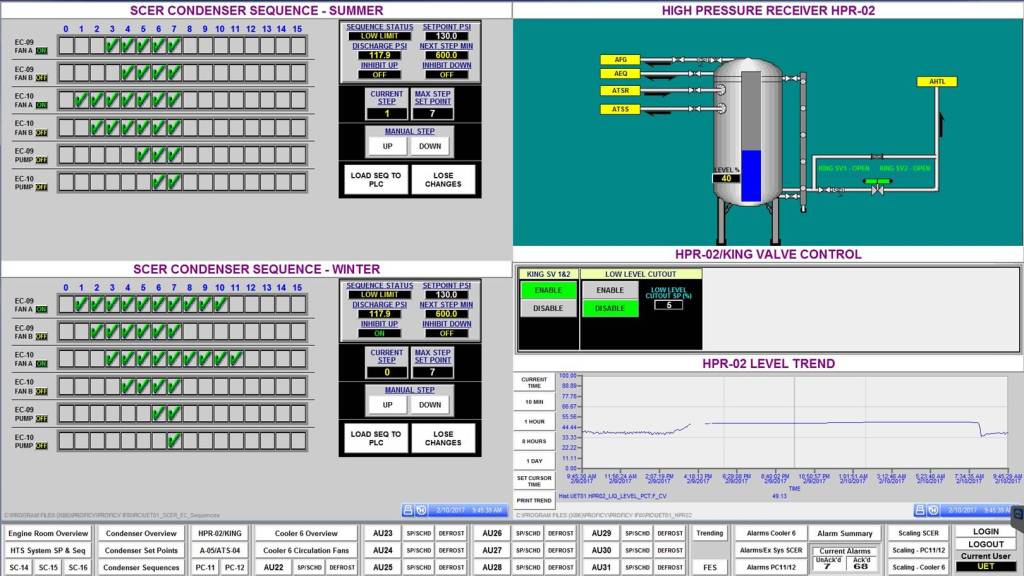

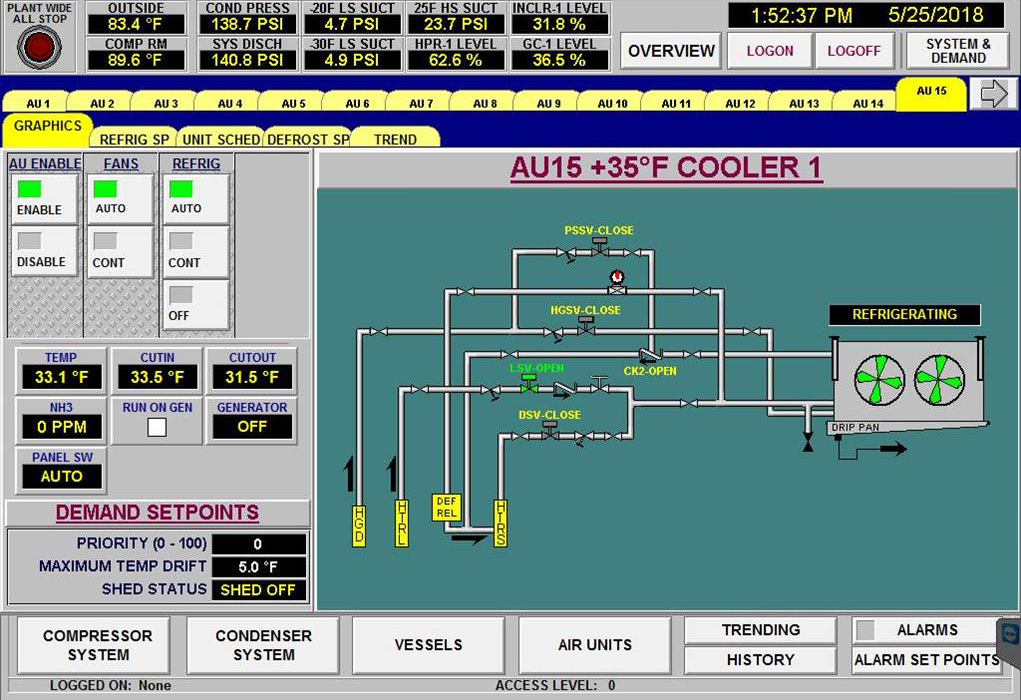

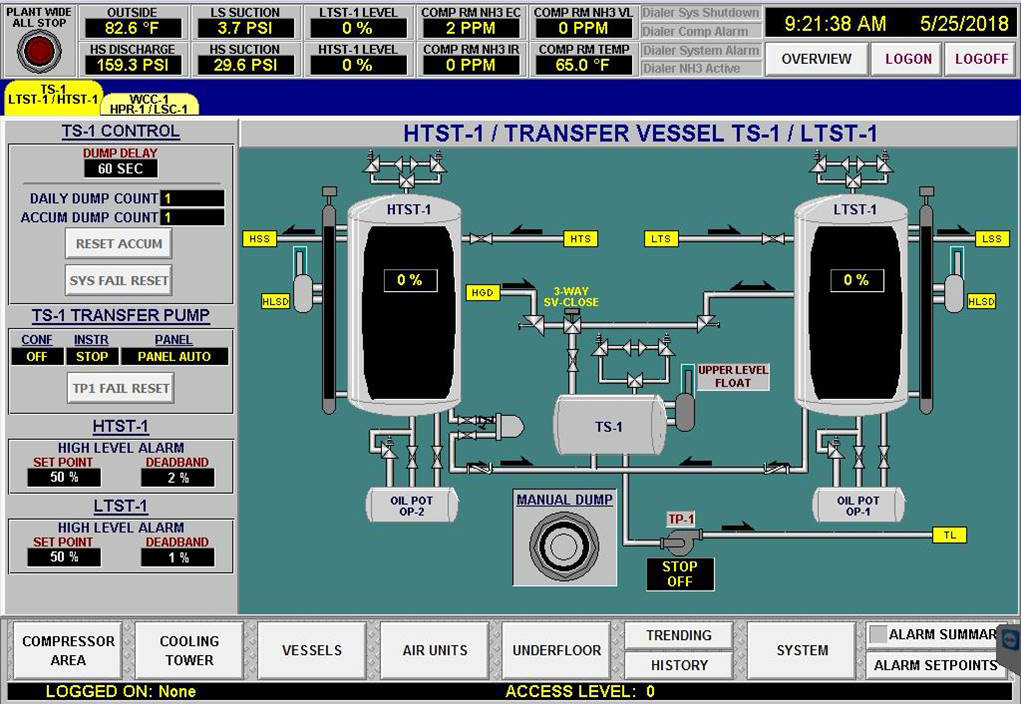

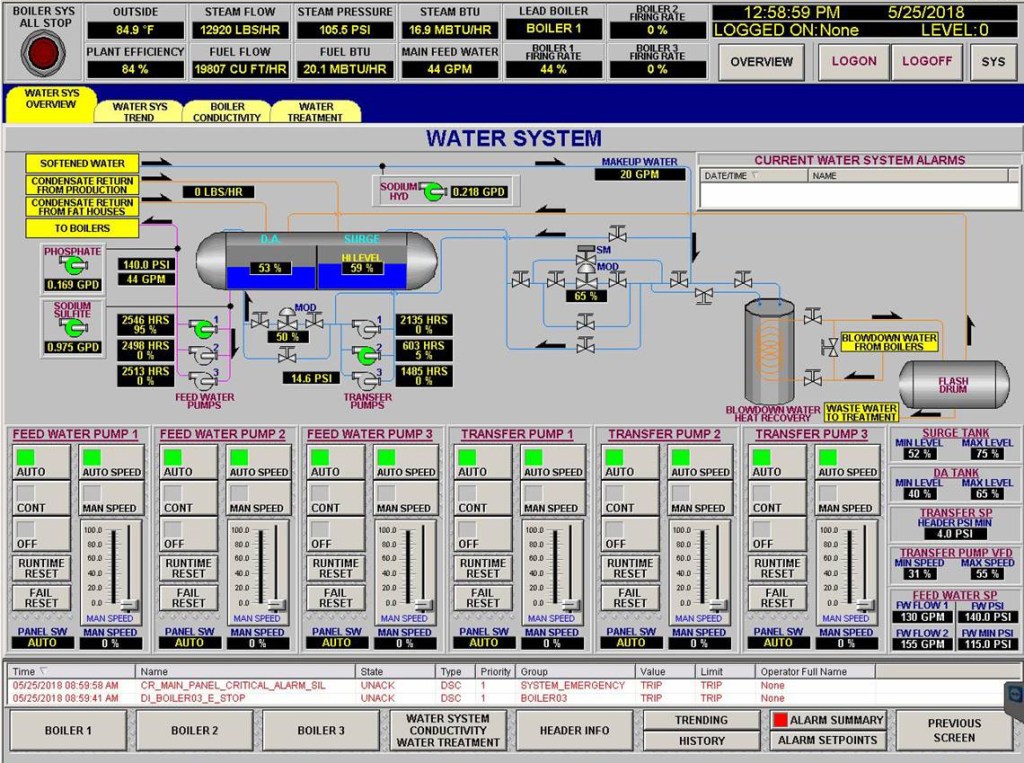

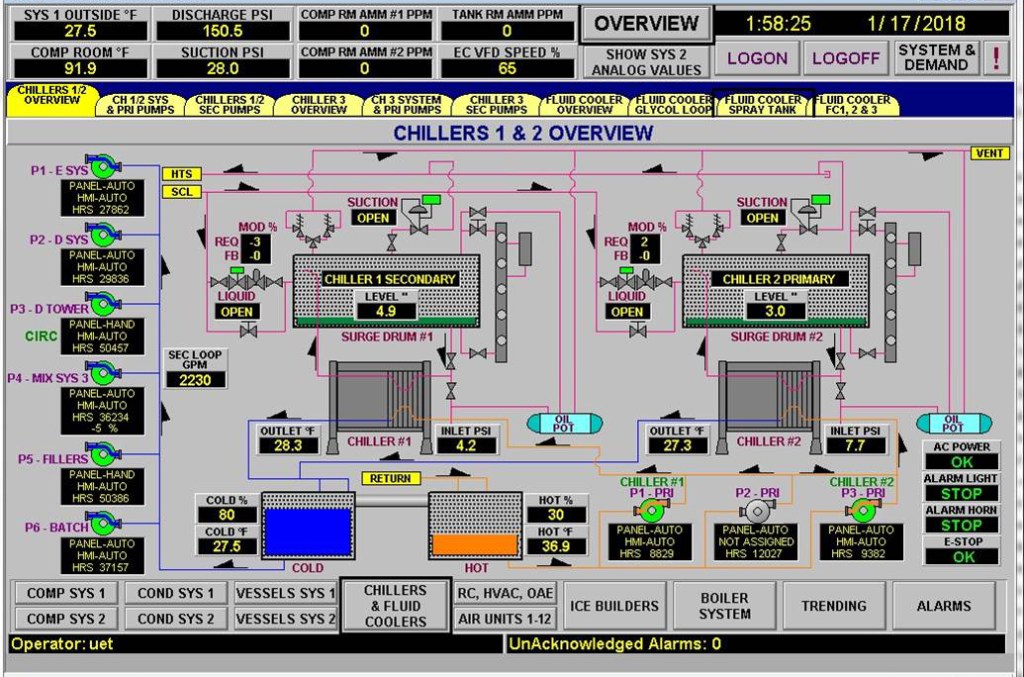

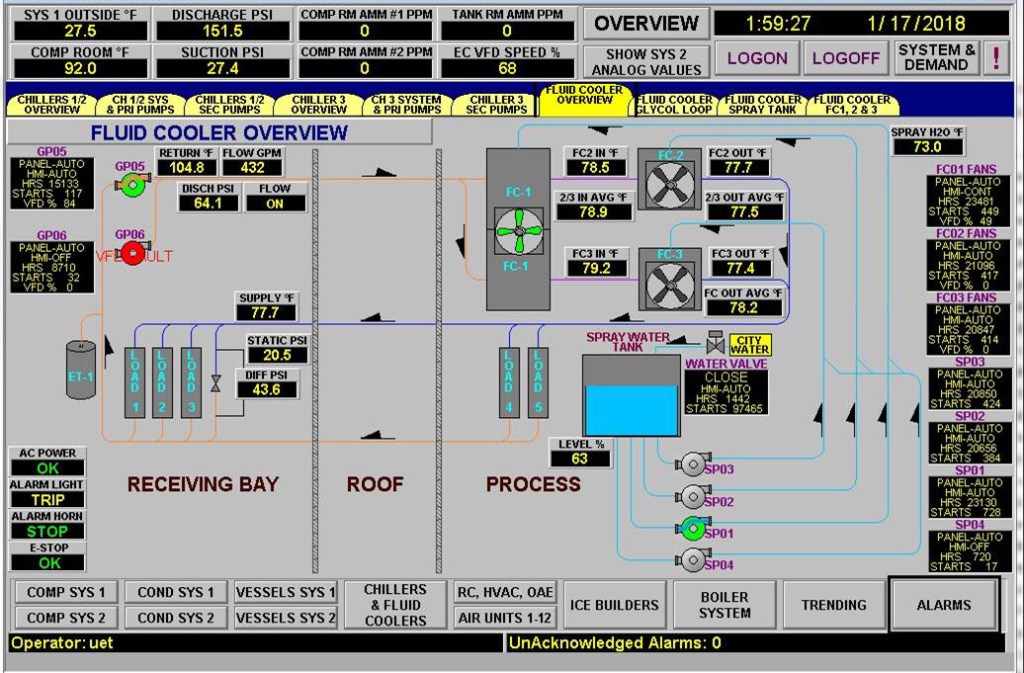

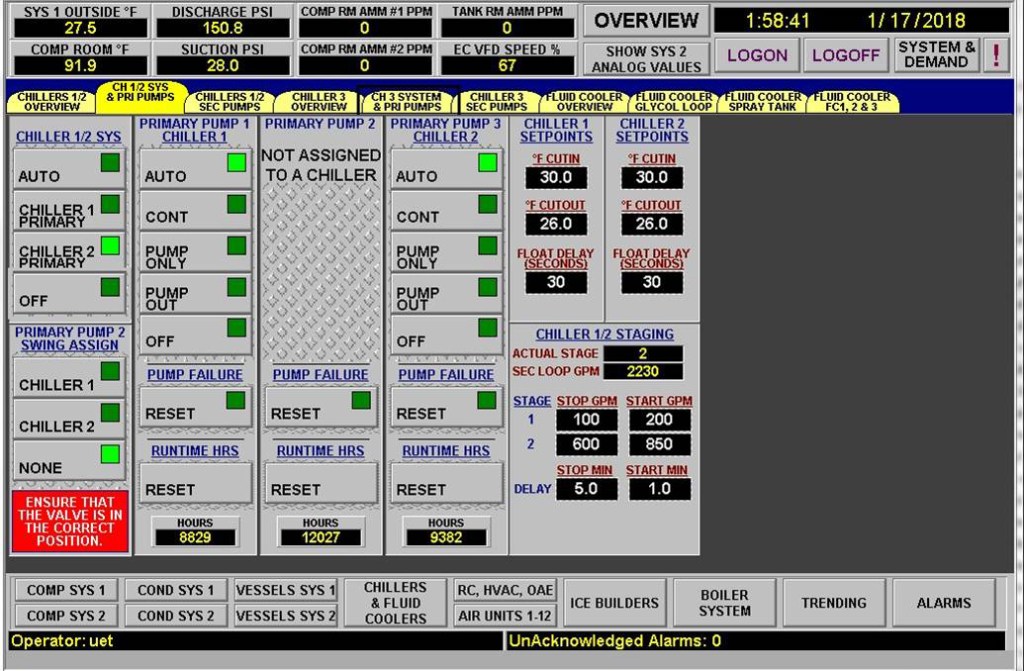

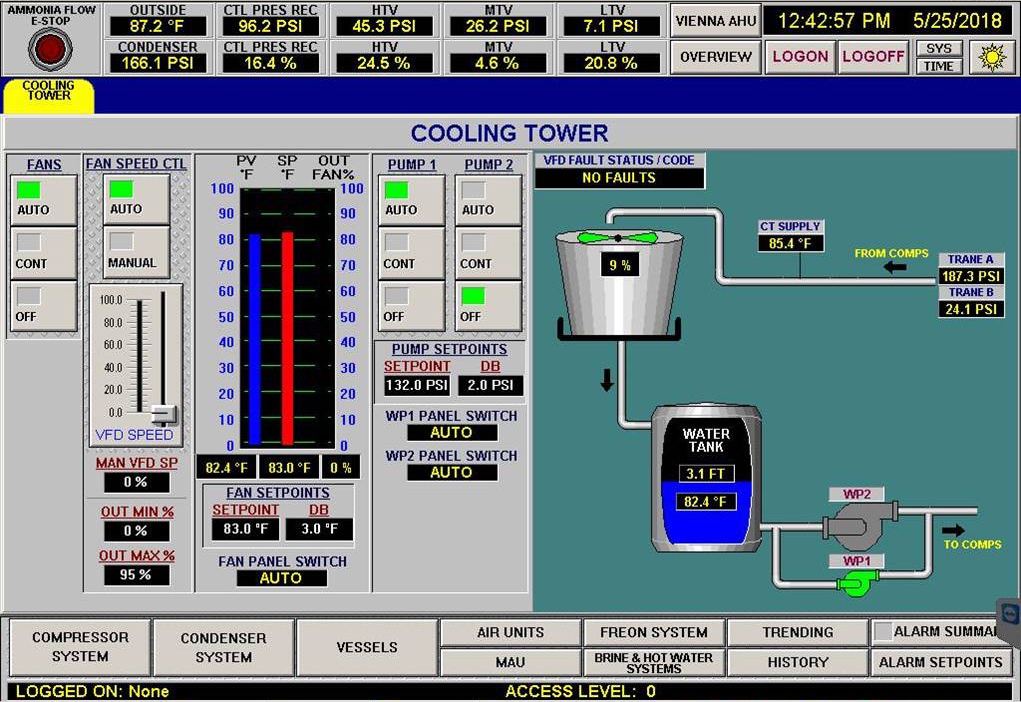

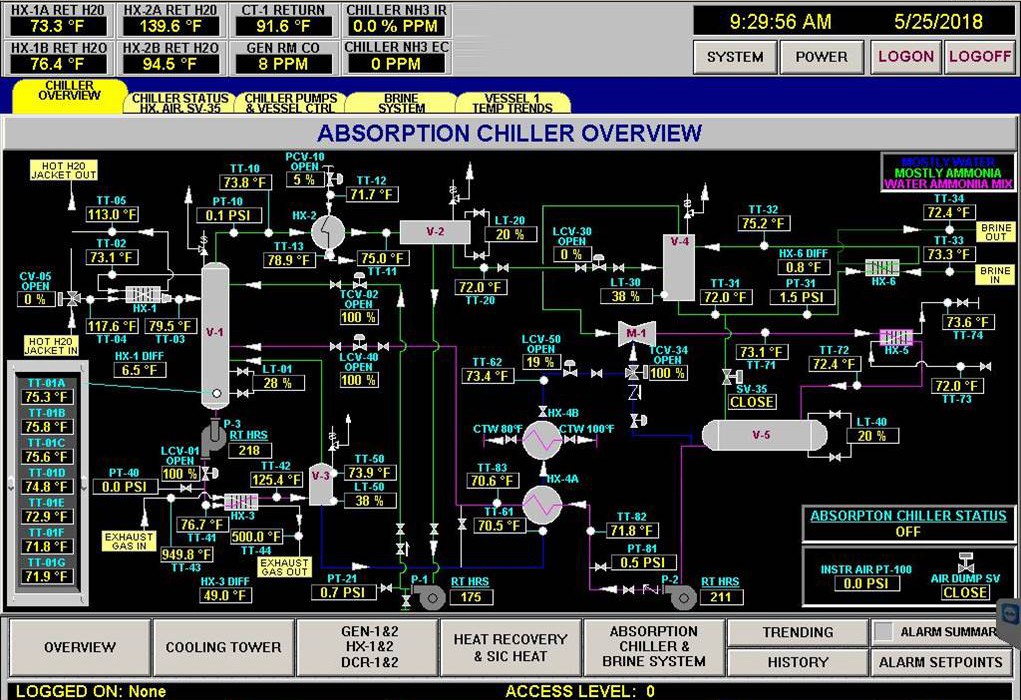

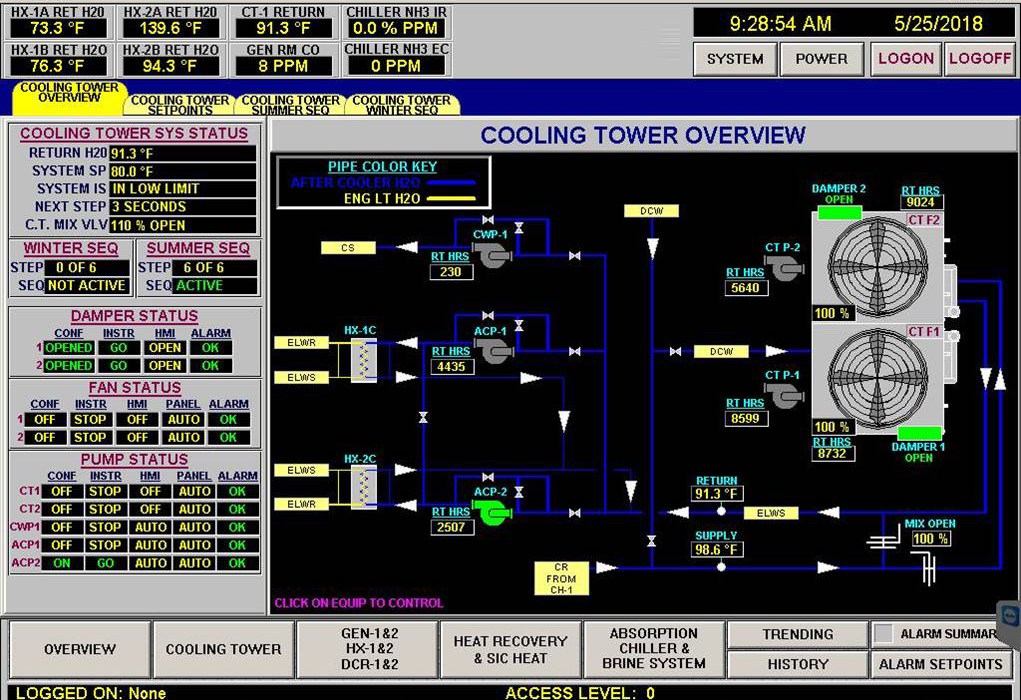

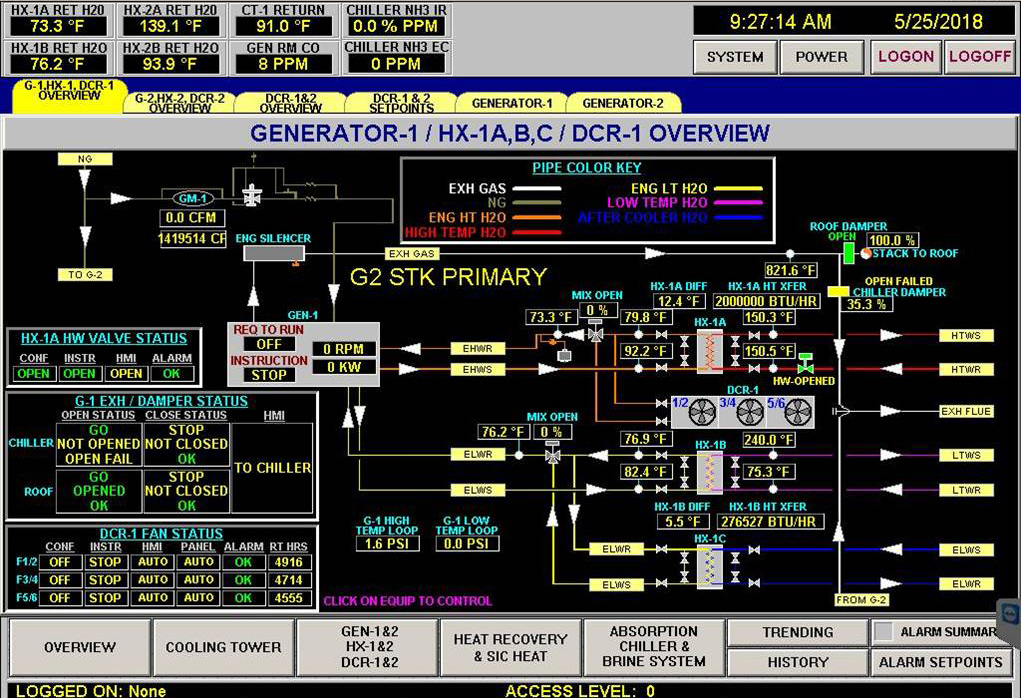

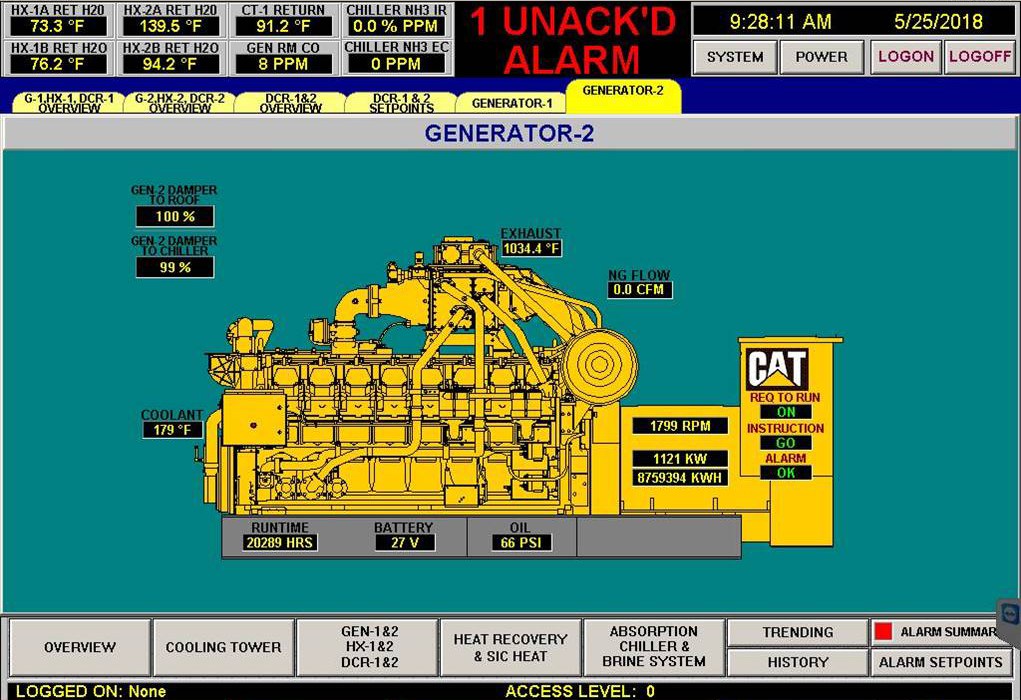

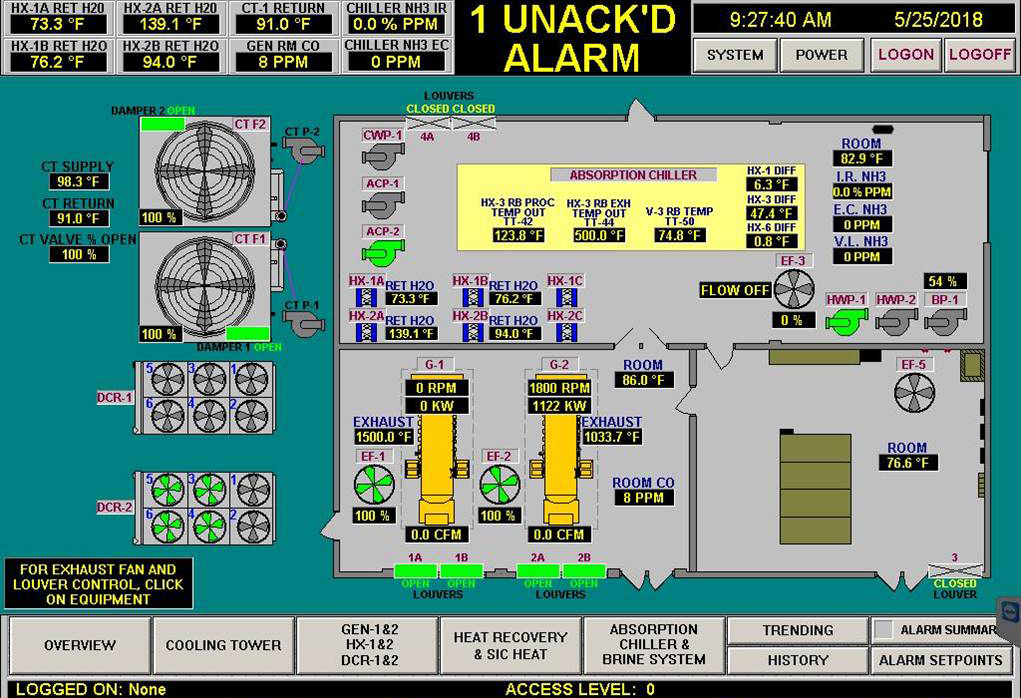

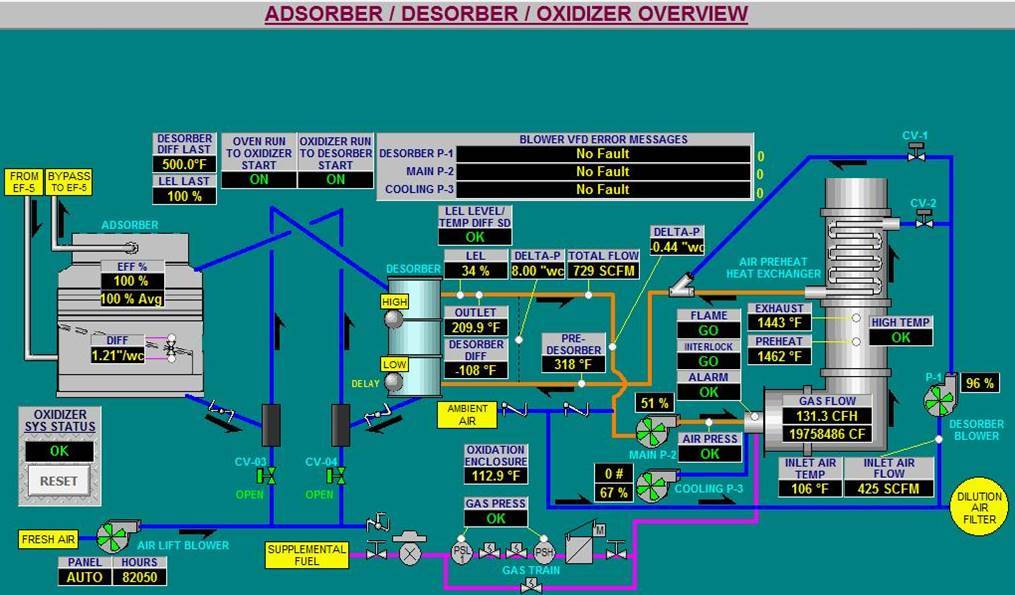

Below are some examples of SCADA system screenshots.